Products

Our fully custom-made products are designed for low maintenance and reduced running costs.

Proven long-selling items support the extended service life of marine vessels.

Proven long-selling items support the extended service life of marine vessels.

-

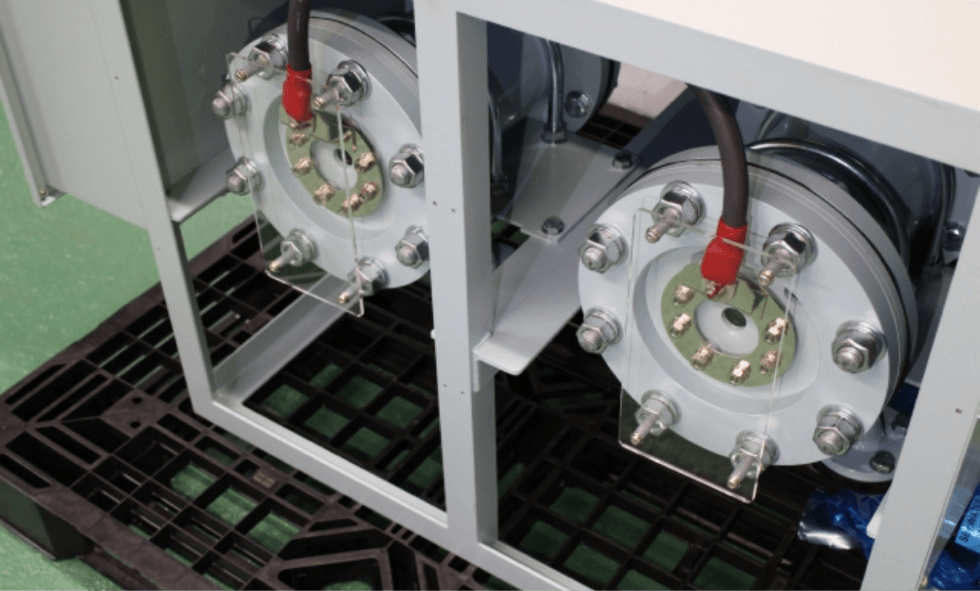

Marine Biofouling Prevention System “Chlorine Attacker”

Powerful self-cleaning using a dual-helical water flow system.This system injects hypochlorous acid—generated by seawater electrolysis—into a ship’s seawater intake to prevent blockage from shellfish larvae.

Powerful self-cleaning using a dual-helical water flow system.This system injects hypochlorous acid—generated by seawater electrolysis—into a ship’s seawater intake to prevent blockage from shellfish larvae.

Its unique dual-helical water flow design reduces buildup of byproducts like magnesium hydroxide, ensuring easy maintenance. With over 30 years of proven performance, it’s also suitable for retrofits and replacements.Marine Growth

Prevention

System -

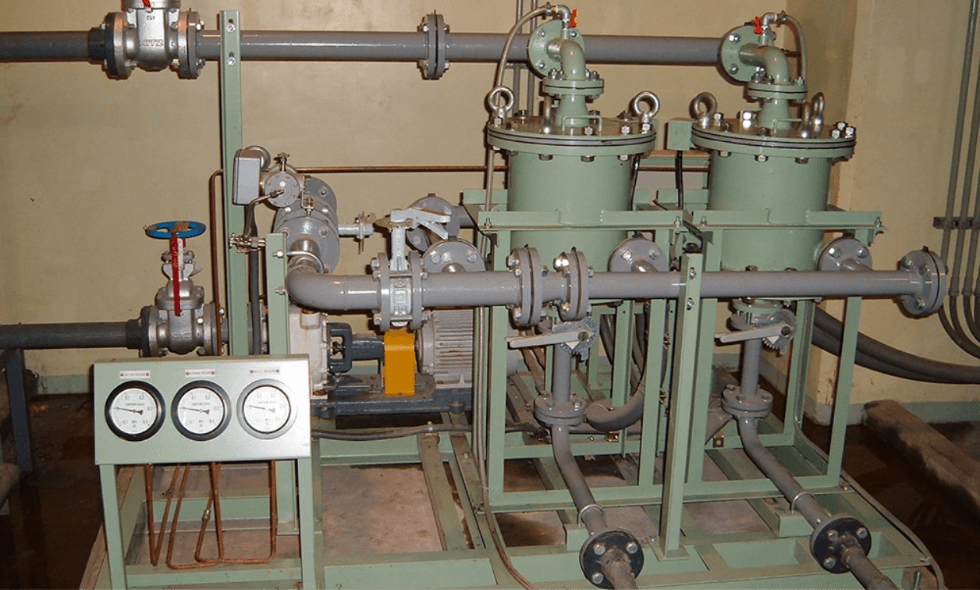

Iron Ion Generator “Feros Protector”

Protects piping with an iron ion coatingThis system electrolyzes mild steel in seawater to produce ferrous ions, which are supplied to cooling water piping to form a protective ferric hydroxide film inside heat exchanger tubes, preventing corrosion.

Protects piping with an iron ion coatingThis system electrolyzes mild steel in seawater to produce ferrous ions, which are supplied to cooling water piping to form a protective ferric hydroxide film inside heat exchanger tubes, preventing corrosion.

Unlike chemical injection methods, it requires no chemical handling or storage, making maintenance easier. It has also been successfully implemented in coastal land-based plant facilities where seawater is available.Iron Ion

Generator -

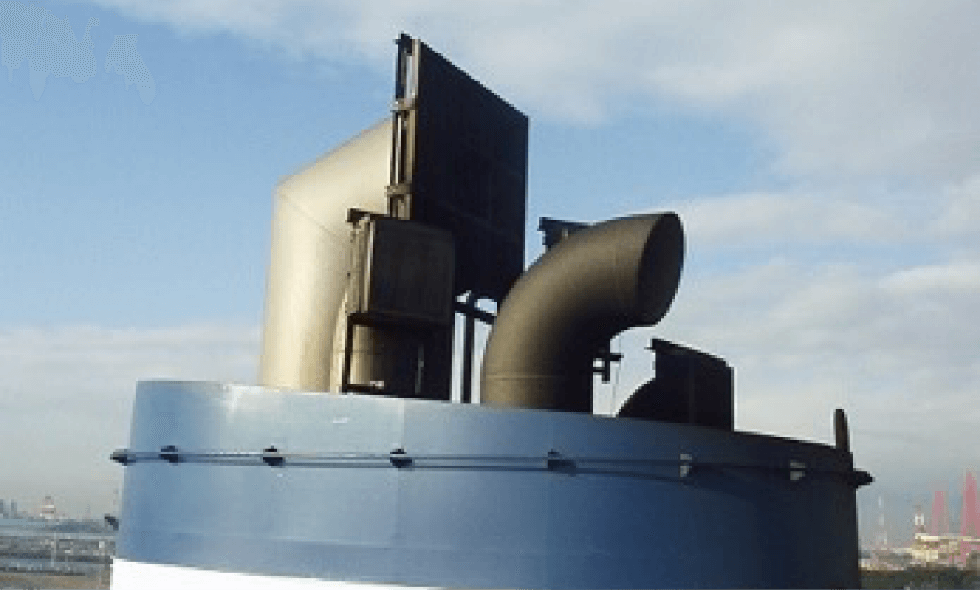

Dust Dispersion Prevention Device

Prevents large-scale dispersion of dust particlesThis device effectively captures and removes dust particles from gas emissions discharged through ship funnels by filtering them through a pyro screen. It helps prevent dust dispersion—particularly during port entry, departure, or docking—thereby avoiding cargo contamination and related issues.

Prevents large-scale dispersion of dust particlesThis device effectively captures and removes dust particles from gas emissions discharged through ship funnels by filtering them through a pyro screen. It helps prevent dust dispersion—particularly during port entry, departure, or docking—thereby avoiding cargo contamination and related issues.

The pyro screen is made of stainless steel, allowing for easy removal, cleaning, and reuse, offering excellent maintenance efficiency.Dust

Suppression

System -

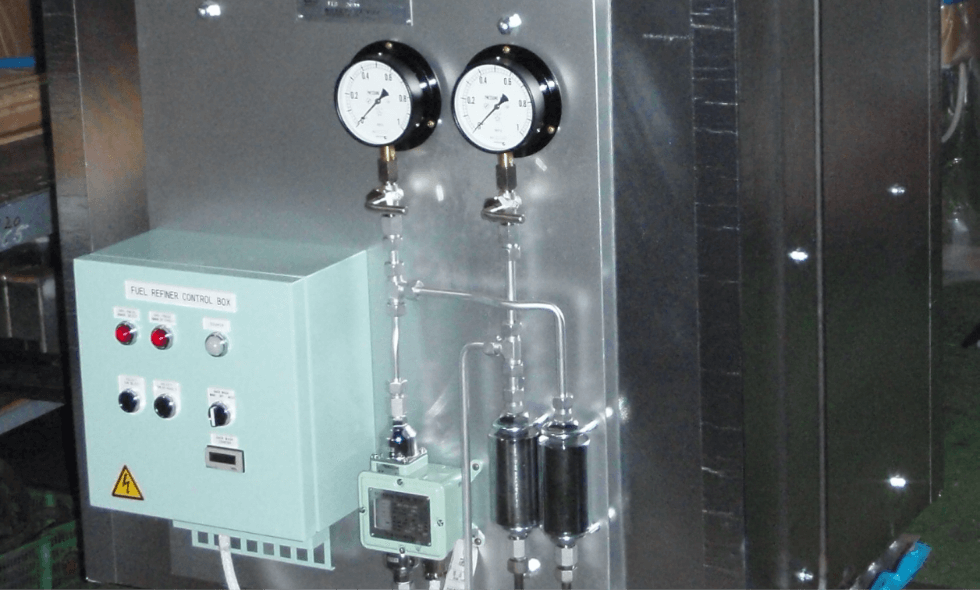

Fuel Oil Treatment System “SELECT”

Removes FCC catalysts and ultra-fine non-combustibles from fuel oil.The SELECT system was designed to address issues arising from the degradation of marine fuel quality. It uses a honeycomb-structured, multi-layered perforated plate element (75μ thick) to ensure both high processing flow and effective separation of fine contaminants such as FCC catalysts and ultra-fine non-combustibles.

Removes FCC catalysts and ultra-fine non-combustibles from fuel oil.The SELECT system was designed to address issues arising from the degradation of marine fuel quality. It uses a honeycomb-structured, multi-layered perforated plate element (75μ thick) to ensure both high processing flow and effective separation of fine contaminants such as FCC catalysts and ultra-fine non-combustibles.

Thanks to its simple design—with no rotating or high-pressure components—it offers stable, safe operation and easy maintenance. The filter elements are also washable and reusable, making the system both efficient and cost-effective over the long term.Fuel Oil

Treatment

System