Engineering

With strengths in electrical, mechanical, refrigeration, and instrumentation technologies—developed over many years in both onshore and offshore fields—we boldly embrace ever-evolving technological innovations. Guided by our quality policy, we provide high-quality support tailored to the detailed needs of our customers.

Power, Public, and Facility Projects

-

Representative Services for Power Generation Equipment Manufacturers

We perform inspection and maintenance of emergency power generation equipment on behalf of manufacturers, handling over 350 cases annually.To ensure that our clients’ emergency gas turbine power generation systems remain in optimal condition, we perform regular inspections and component replacements under manufacturer contracts. Depending on the equipment, fire protection systems may also be included. In such cases, certified personnel conduct semiannual and annual inspections in accordance with Japan’s Fire Service Act.

We perform inspection and maintenance of emergency power generation equipment on behalf of manufacturers, handling over 350 cases annually.To ensure that our clients’ emergency gas turbine power generation systems remain in optimal condition, we perform regular inspections and component replacements under manufacturer contracts. Depending on the equipment, fire protection systems may also be included. In such cases, certified personnel conduct semiannual and annual inspections in accordance with Japan’s Fire Service Act.

Our services include the inspection and maintenance of power distribution panels, simplified testing of circuit breakers, relay protection system checks, and inspection of starting and control storage batteries. We also handle bearing replacements for generators and motors, as well as inspection and replacement of electrical components such as sensors for gas engines and gas turbines.

In addition to these maintenance services, we also conduct on-site test runs and tuning for both regular and emergency power generation equipment.

With over two decades of experience in this field, we now handle more than 350 on-site projects per year. Trusted by manufacturers, we serve as a vital bridge between them and end-users, continuing our mission with dedication each day.Production

Agency

Manufacturers -

Inspection services for engines and turbochargers in emergency and regular power generation systems at plant facilities, hospitals, factories, and building infrastructures.

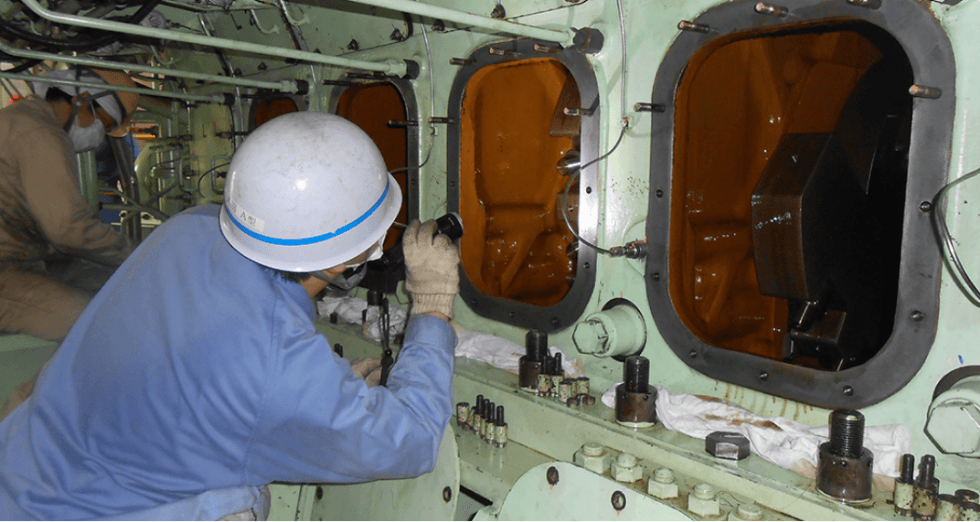

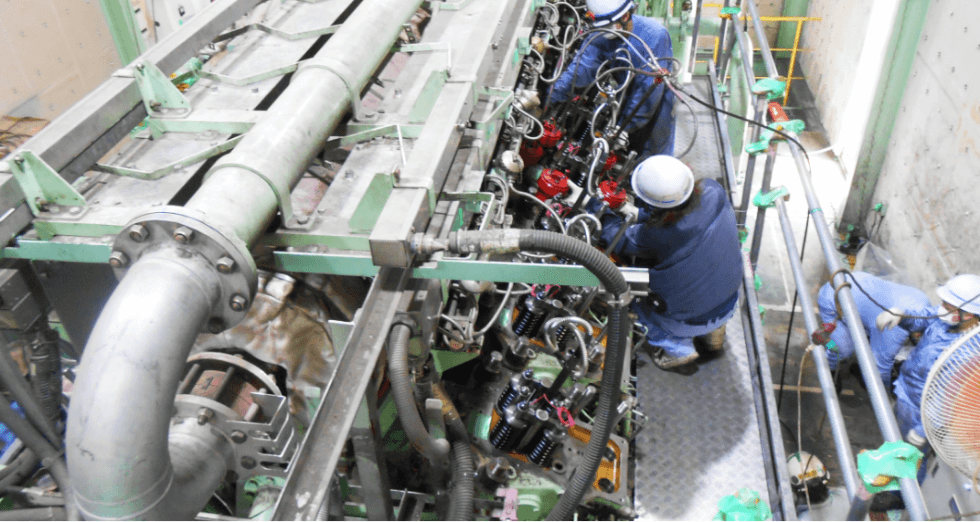

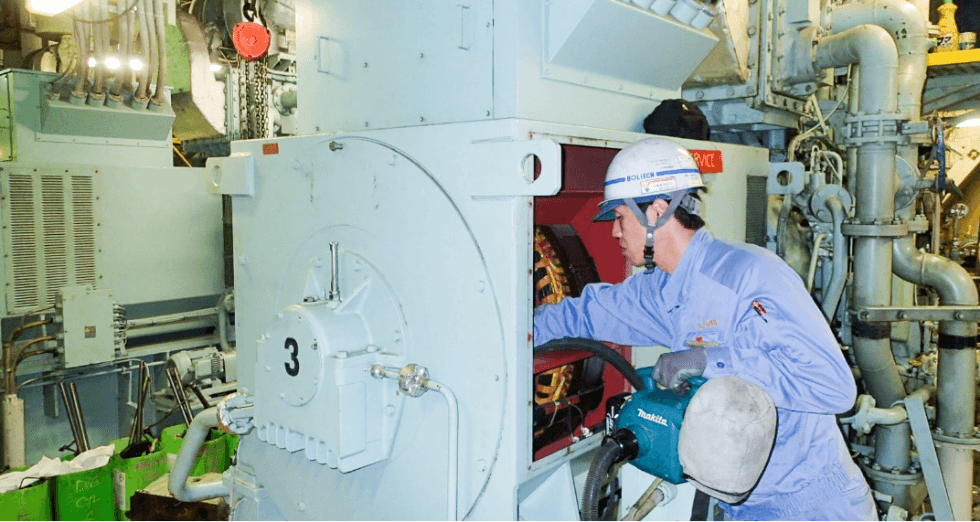

We provide inspection and maintenance services to ensure the stable operation of engines and turbochargers.EngineWe inspect and maintain engines used to power ships and generate electricity in power plants. While powerful, these engines are also delicate. Our maintenance services ensure stable operation, providing our customers with peace of mind.TurbochargerTurbochargers boost engine output and are essential components installed in engines ranging from automobiles to ships. Due to their high-speed rotation, regular inspection and maintenance are crucial to ensure safe and reliable operation.Engine

We provide inspection and maintenance services to ensure the stable operation of engines and turbochargers.EngineWe inspect and maintain engines used to power ships and generate electricity in power plants. While powerful, these engines are also delicate. Our maintenance services ensure stable operation, providing our customers with peace of mind.TurbochargerTurbochargers boost engine output and are essential components installed in engines ranging from automobiles to ships. Due to their high-speed rotation, regular inspection and maintenance are crucial to ensure safe and reliable operation.Engine

Turbochargers -

Inspection, Maintenance, and Repair Services for Onshore Reefer Containers

Refurbished used reefer containers are repurposed for use as refrigerators or freezers—repair services are also available.Most of the reefer containers we handle are second-hand units used for over ten years in maritime transport. After refurbishment, they are repurposed for land-based use—such as in factories, farms, ranches, and fishing ports—as refrigerators or freezers. Simply supply electricity, and they’re ready to use.

Refurbished used reefer containers are repurposed for use as refrigerators or freezers—repair services are also available.Most of the reefer containers we handle are second-hand units used for over ten years in maritime transport. After refurbishment, they are repurposed for land-based use—such as in factories, farms, ranches, and fishing ports—as refrigerators or freezers. Simply supply electricity, and they’re ready to use.

We also modify containers for special purposes like temperature-controlled storage or experimental use, offering proposals tailored to customer needs. In partnership with leasing and sales companies, we inspect, repair, and refurbish containers before delivery. If issues arise, we provide on-site maintenance and repairs.

With a stock of parts from major manufacturers, we can quickly respond to repair requests. Need a specific part? Feel free to contact us.Inspection

And

Repair -

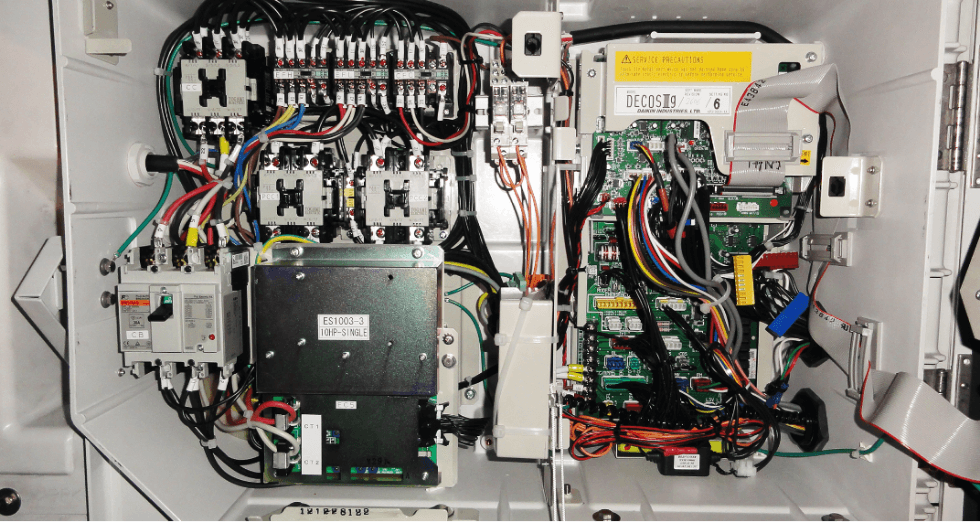

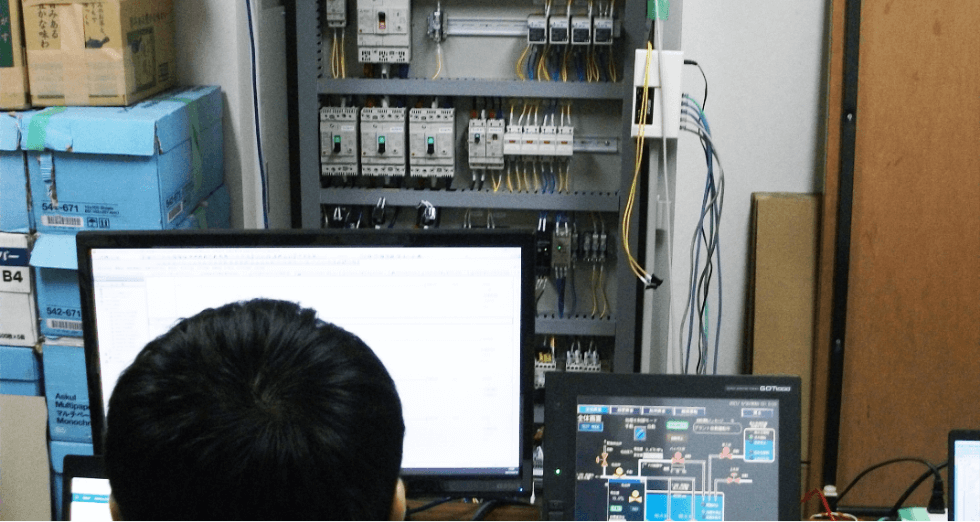

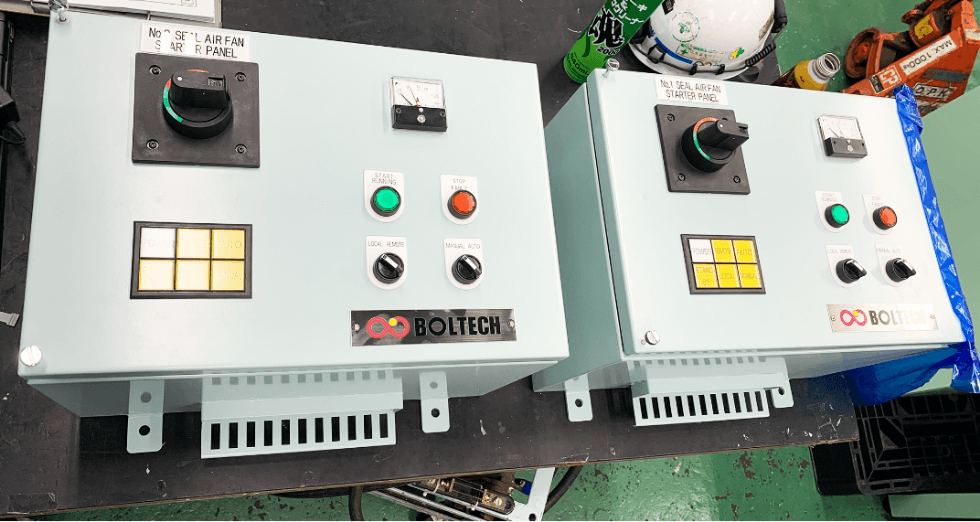

Engineering services encompassing alternative proposal, design, fabrication, and retrofitting of electrical installations and control equipment through custom-built manufacturing processes.

We provide end-to-end services for the design, manufacturing, installation, and upgrade proposals of onshore electrical systems.We provide end-to-end services for the design, manufacturing, and installation of onshore electrical systems and equipment on a made-to-order basis. We also handle upgrades and replacements of aging or discontinued equipment, offering alternative solutions.

We provide end-to-end services for the design, manufacturing, installation, and upgrade proposals of onshore electrical systems.We provide end-to-end services for the design, manufacturing, and installation of onshore electrical systems and equipment on a made-to-order basis. We also handle upgrades and replacements of aging or discontinued equipment, offering alternative solutions.

From custom control panel design to on-site installation and test operation, we deliver user-focused proposals backed by our experience in plant maintenance. Even without existing documentation, our engineers conduct on-site surveys to ensure accurate support.

Our products have been installed in various plants and commercial buildings across Japan, and we’re fully equipped to handle large-scale electrical renovations.Proposal

Design and

Refurbishment

Marine & Offshore Projects

Dust Dispersion Prevention Devices

Marine Biofouling Prevention Systems

Iron Ion Generators

Fuel Oil Treatment Systems

Remote Main Engine Control Systems

Generators

Electric Motors

Propeller Control Systems

バラスト水処理装置

Main Switchboards, Charging/Discharging Panels, Generator Panels, and Starters for Ships

Chip Unloader Systems

Deck Machinery

Thruster Control Systems

-

Representative Services for Marine Equipment Manufacturers

From initial vessel commissioning to maintenance and repair — we provide global support.Ships vary greatly depending on their purpose—whether cargo vessels, tugboats, or specialized ships—and each is equipped with a wide range of devices and systems.

From initial vessel commissioning to maintenance and repair — we provide global support.Ships vary greatly depending on their purpose—whether cargo vessels, tugboats, or specialized ships—and each is equipped with a wide range of devices and systems.

Through partnerships with domestic and international manufacturers, we offer total support from commissioning to inspection, maintenance, repairs, and retrofitting. Since vessels operate globally without rest, we provide worldwide service to meet these demands.

With our motto “Anytime, Anywhere, Anything,” we’re committed to supporting the essential role of maritime transport around the world.Marine

Equipment

Manufacturer

-

Inspection, Maintenance, and Repair of Marine Equipment

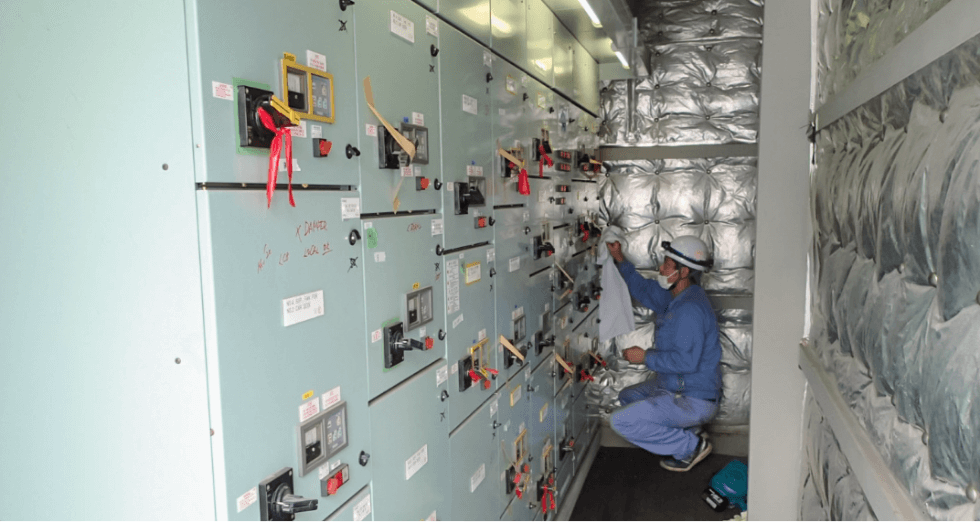

We provide inspection and maintenance services to ensure the stable operation of engines and turbochargers.Ships are equipped with a wide range of devices and systems, all of which require regular inspection and maintenance. Among them, we mainly perform inspections and maintenance of main switchboards and engine remote control systems upon customer request.

We provide inspection and maintenance services to ensure the stable operation of engines and turbochargers.Ships are equipped with a wide range of devices and systems, all of which require regular inspection and maintenance. Among them, we mainly perform inspections and maintenance of main switchboards and engine remote control systems upon customer request.

As the saying goes, “anything with form will eventually break.” Even well-maintained equipment can experience faults due to harsh operating environments. We respond to such unexpected issues by identifying the cause and performing necessary repairs.

The trust we’ve earned wasn’t given—it’s the result of years of hands-on work, technical expertise, and sincere responses to a variety of on-site customer needs under partnerships with equipment manufacturers. On vessels in operation, we make the most of limited time to deliver the highest performance possible.Inspection and

Repair for

M.Equipment -

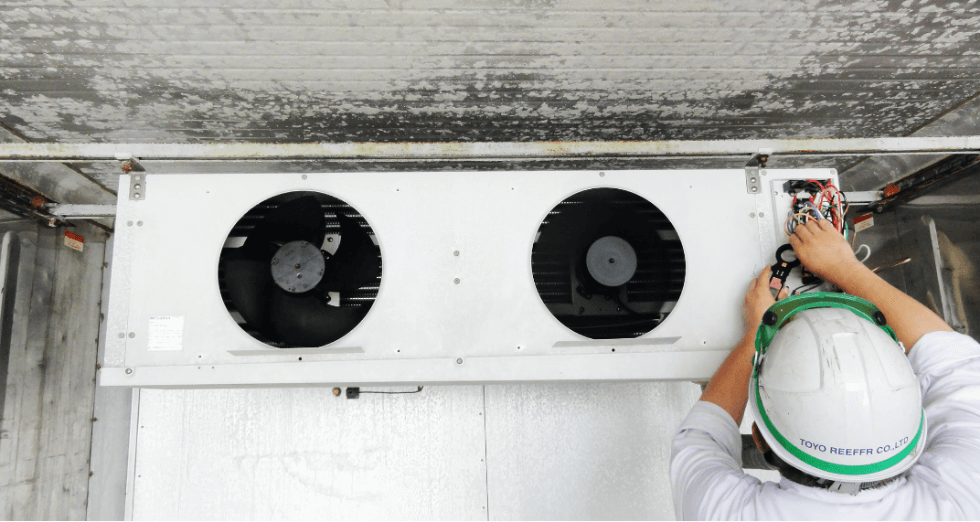

Inspection, Maintenance, and Repair Services for Marine Reefer Containers

Inspection, maintenance, and repair of reefer containers conducted at Oi Container Terminal.At Oi Container Terminal—the largest in Tokyo Port—we provide inspection, maintenance, and repair services for marine reefer containers. These refrigerated containers keep cargo at a stable temperature during ocean transport.

Inspection, maintenance, and repair of reefer containers conducted at Oi Container Terminal.At Oi Container Terminal—the largest in Tokyo Port—we provide inspection, maintenance, and repair services for marine reefer containers. These refrigerated containers keep cargo at a stable temperature during ocean transport.

Before loading, we perform Pre-Trip Inspections (PTI), and if issues are found, we carry out necessary repairs. With over 40 years of experience, we began as an agent for Mitsubishi Heavy Industries and are now certified to handle parts from Daikin and Carrier Transicold. We’re proud to continue supporting this essential port.Inspection and

Repair for M.

Reefer Container -

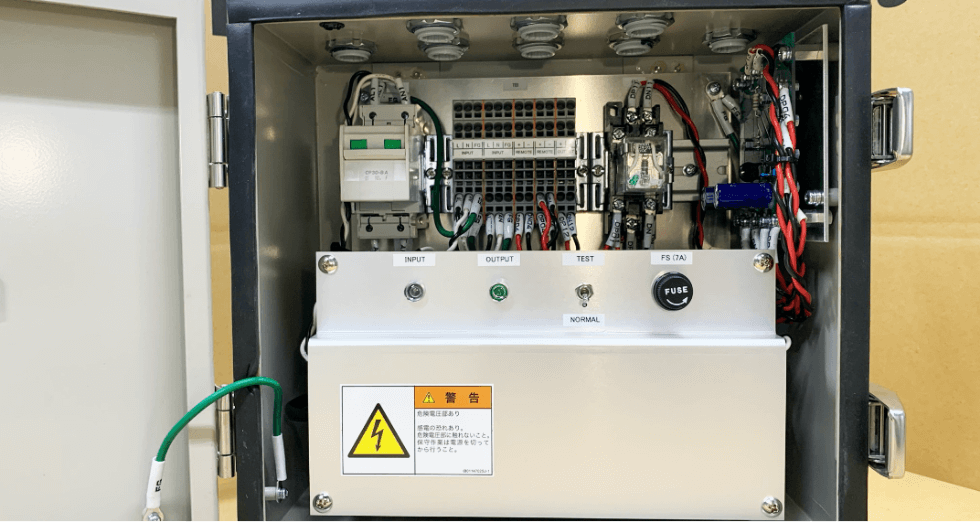

Custom Electrical and Control Equipment: Retrofit Proposals, Design, Manufacturing, and Renovation Work

End-to-end support for the design, installation, and upgrade proposals of marine electrical systems.We provide full-service support for the design, manufacturing, and installation of custom marine electrical systems and equipment, including wiring design and construction. We also handle upgrades and replacements of aging or discontinued systems, offering alternative solutions tailored to each vessel.

End-to-end support for the design, installation, and upgrade proposals of marine electrical systems.We provide full-service support for the design, manufacturing, and installation of custom marine electrical systems and equipment, including wiring design and construction. We also handle upgrades and replacements of aging or discontinued systems, offering alternative solutions tailored to each vessel.

Our services include the design, production, installation, and commissioning of custom control panels, as well as proposals for replacing outdated equipment no longer supported by manufacturers. Drawing on extensive knowledge from marine equipment maintenance, we offer user-focused solutions—even in cases where existing documentation is limited, our engineers can perform on-board inspections.

We have a strong track record of installations on domestic, international, and government vessels, and our experience extends to shipyards and dockside work worldwide—enabling us to meet a wide range of customer needs.Proposal Design

Refurbishment

Retrofit -

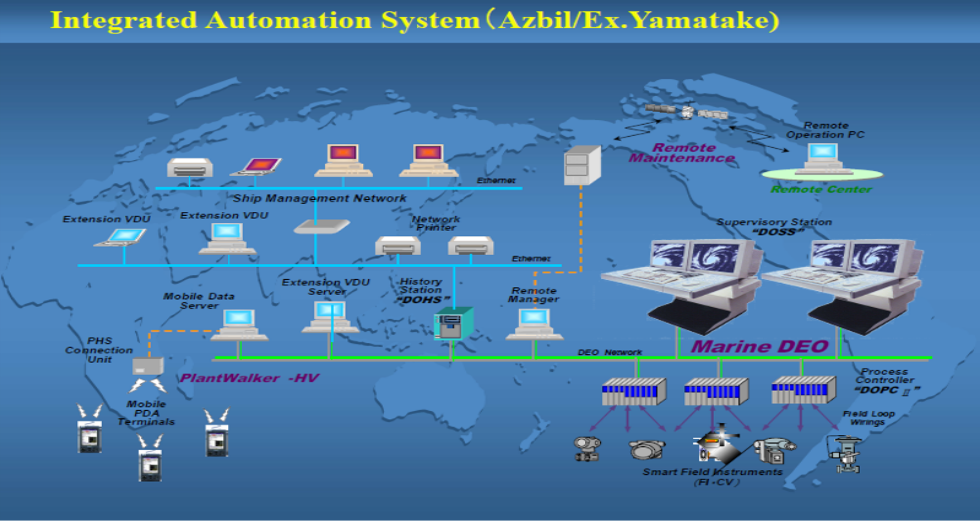

Maintenance of Integrated Automation Systems (IAS/IMS) for LNG Vessels

Commissioning, test operation, and maintenance of the IAS “Marine-DEO” for LNG vessels.We provide comprehensive services for distributed Integrated Automation Systems (IAS) installed on newly built LNG vessels, including startup, commissioning, and trial operation. After the vessel enters service, we continue to support safe operation through regular inspections, system modifications, specification changes, and optimization retrofits—all backed by engineering expertise and tailored proposals.

Commissioning, test operation, and maintenance of the IAS “Marine-DEO” for LNG vessels.We provide comprehensive services for distributed Integrated Automation Systems (IAS) installed on newly built LNG vessels, including startup, commissioning, and trial operation. After the vessel enters service, we continue to support safe operation through regular inspections, system modifications, specification changes, and optimization retrofits—all backed by engineering expertise and tailored proposals.

Our work ensures the reliability of the control system environment essential for safe navigation. In addition, we supply key equipment and consumable parts needed for ongoing maintenance and inspections.Commissioning and Maintenance of Engine Monitoring Systems (Data Logger)We handle commissioning, trial operation support, after-sales maintenance, and parts supply for advanced engine monitoring systems (data loggers) that provide centralized monitoring of main engines, generators, boilers, and auxiliary equipment—ensuring stable and high-performance operation through system redundancy.

When upgrading aging systems, we offer seamless replacements that preserve the features of existing equipment while enhancing functionality. We also propose, engineer, and supply simplified monitoring systems using the latest PLC technology, contributing to the safe and efficient operation of vessels.LNG Vessel

IAS/IMS

Maintenance -

Maintenance of Instrumentation and Control Systems for General Vessels

Marine Instrumentation and Control EquipmentWe handle a wide range of marine instrumentation and control equipment for ship automation systems, including field instruments, pressure transmitters, control valves, compact controllers, electronic recorders, and signal converters.

Marine Instrumentation and Control EquipmentWe handle a wide range of marine instrumentation and control equipment for ship automation systems, including field instruments, pressure transmitters, control valves, compact controllers, electronic recorders, and signal converters.

Backed by proven technical expertise, we provide maintenance support to ensure reliable automation for both marine and land-based plants. We also offer sales of equipment and supply of consumable parts.General Vessel

I&C

Maintenance -

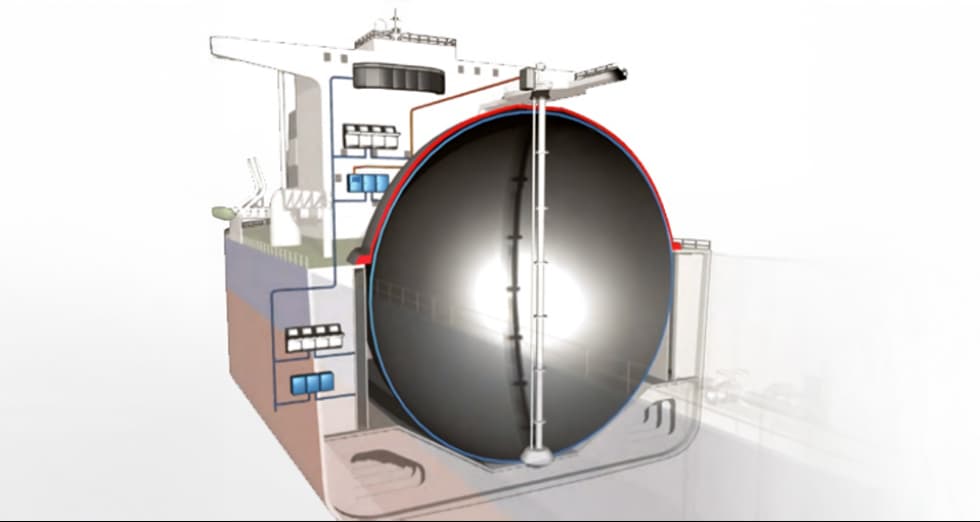

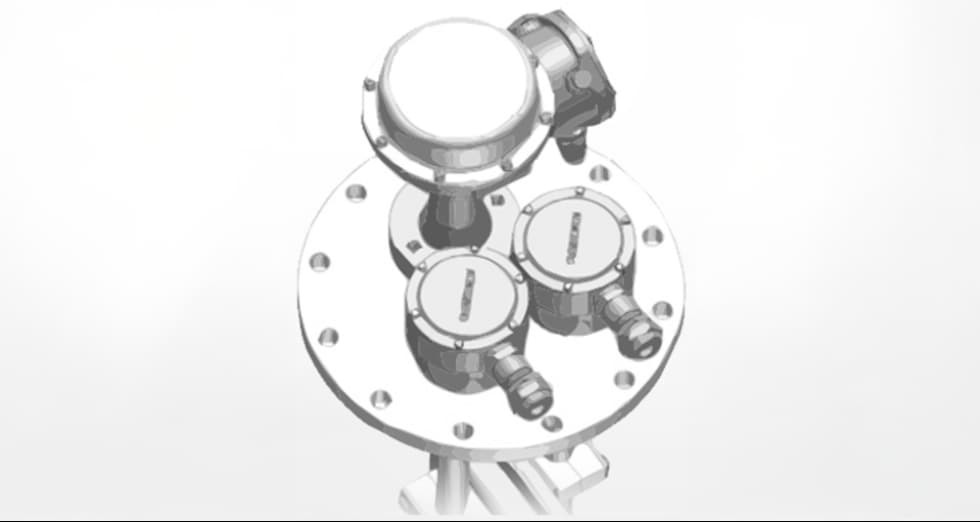

Maintenance of Radar-Type Level Gauging and Fire Alarm Systems for CTS Applications

Radar-Type Level Gauging System for CTS ApplicationsWe provide maintenance and inspection support for radar-type level gauging systems from Norway’s Kongsberg Maritime, ensuring high-precision measurement accuracy for cargoes such as LNG and LPG. Our services help maintain the reliability and accuracy of cargo monitoring throughout transport.Fire Alarm SystemWe provide commissioning and after-sales maintenance for fire alarm systems from Norway’s Autronica, contributing to the safe operation of vessels.

Radar-Type Level Gauging System for CTS ApplicationsWe provide maintenance and inspection support for radar-type level gauging systems from Norway’s Kongsberg Maritime, ensuring high-precision measurement accuracy for cargoes such as LNG and LPG. Our services help maintain the reliability and accuracy of cargo monitoring throughout transport.Fire Alarm SystemWe provide commissioning and after-sales maintenance for fire alarm systems from Norway’s Autronica, contributing to the safe operation of vessels.

We also offer proposals and installation services for system upgrades in response to aging equipment.CTS Radar Level

& Fire Alarm

System Mainten -

Boiler Combustion Control Systems and Plant Instrumentation Systems

Marine Boiler Combustion Control SystemWe design and manufacture marine boiler combustion control systems tailored to each vessel’s specifications. Our services include system integration, commissioning, ignition and combustion tuning, and load adjustment for newbuild vessels.

Marine Boiler Combustion Control SystemWe design and manufacture marine boiler combustion control systems tailored to each vessel’s specifications. Our services include system integration, commissioning, ignition and combustion tuning, and load adjustment for newbuild vessels.

For ships in service, we offer routine inspections during dockings, maintenance of control devices, and supply of spare parts. We also support SOx reduction retrofits in line with IMO environmental regulations, providing comprehensive solutions for boiler combustion control.Plant Instrumentation SystemLaunched as a division of our company in July 2022 through a business transfer from our parent company, this unit focuses on instrumentation systems for land-based power generation plants.

We provide proposals, supply, and after-sales support for all process-related equipment—including sensors for variables such as pressure, flow, and temperature, as well as process control devices. Our services contribute to safe, reliable, and energy-efficient plant operations.Monitoring Instrument Panels for Power PlantsMonitoring Instrument Panels for Power PlantsExhaust Gas AnalyzerThe emission of air pollutants is regulated by law, and exhaust gases from combustion equipment and fuel-burning systems must be regularly measured and recorded.

Analyzing exhaust gases also provides valuable insights into combustion conditions and energy efficiency.BCCS and PIS -

SOx Scrubber (EGCS) Measurement, Monitoring, and Control System

Exhaust Gas Cleaning System (EGCS) for Marine VesselsThrough a maintenance and technical partnership with Ecospray Technologies Srl. (EST), we provide comprehensive services for EGCS (Exhaust Gas Cleaning Systems) installed on both newbuild and retrofitted vessels in Japan. Our offerings include commissioning, testing, after-sales maintenance, and periodic inspections to ensure optimal system performance.

Exhaust Gas Cleaning System (EGCS) for Marine VesselsThrough a maintenance and technical partnership with Ecospray Technologies Srl. (EST), we provide comprehensive services for EGCS (Exhaust Gas Cleaning Systems) installed on both newbuild and retrofitted vessels in Japan. Our offerings include commissioning, testing, after-sales maintenance, and periodic inspections to ensure optimal system performance.

By supporting the effective operation of EGCS, we contribute to reducing SOx and CO₂ emissions, as well as the removal of PM and soot—actively promoting environmental protection and supporting the goals of the SDGs.Measurement

MonitoringCS

of SOxEGCS